We have unique facilities for environmental testing here at SSL. These facilities allow our engineers to do multiple checks along the way, throughout the design process, instead of waiting for the final flight test to discover problems. For example, we have several thermal vacuum chambers where engineers can chill and bake instruments to simulate the conditions they will be exposed to in space. Our thermal vacuum chambers accommodate full mechanical deployments of instruments, at temperatures from above 100℃ to well below -100℃. We have the ability to run all of our electronics inside the chambers and make sure they function correctly. We can even do full G-negated deployments of antennas and booms up to 7 meters in length inside specially-built chambers.

Silver 320 Calibration Chamber

With manipulator, Ion/Electrostatic Detectors

Silver 320 Small Calibration Chamber

With manipulator, Ion/Electrostatic Detectors

Silver Bayside Chamber

- 36cuft Thermal Vacuum chamber with 100℃ to -80℃ temperature range at ultimate pressure 1×10-7torr.

- 26”w x 28”d mountable space with 1/4×28 screws in 2”x2” grid (approximately 12.5ft^3 total).

- 12 Type T thermocouples for customer use integrated into the system’s Thermal controller.

- Camera/lighting system to 60C. TQCM, RGA.

- Attached to ISO 3 Class 1000 clean room.

- Electrical feed-thrus present.

Silver Bertha Chamber

- Large 750 ft^3 Thermal Vacuum chamber with 44Dx80Lx24H test area ( approximately 50ft^3 ).

- Temperature range of 100℃ to -60℃ at ultimate pressure of 1×10-6 torr.

- Instrumented with 28 t-type thermocouples for instrument monitoring, RGA and TQCM.

- Electrical feed-thrus present.

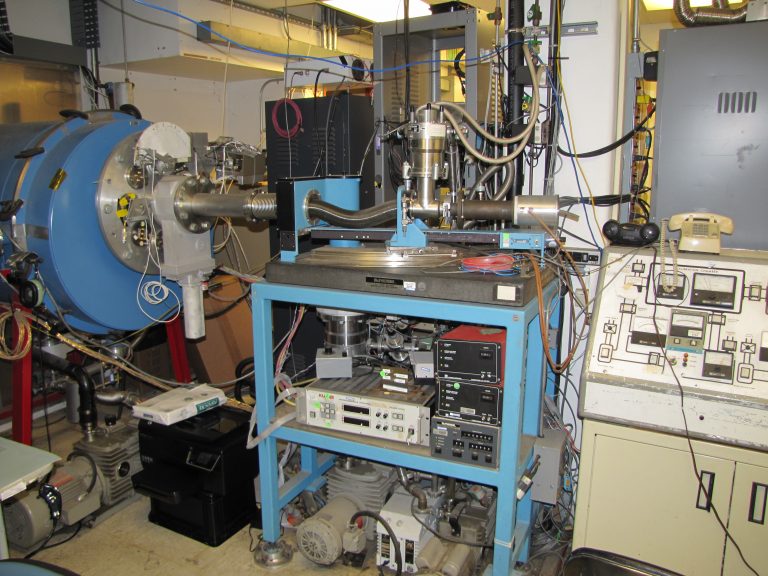

EUV/FUV Calibration Chamber

- Allows the calibration of ultraviolet imaging instruments between 50-180 nm.

- Several light sources provide either broadband or line emissions in the ultraviolet.

- A manipulator system inside the vacuum chamber allows for the horizontal and vertical motion and the rotation of instruments.

Jeffrey Chamber

- 36 ft^3 Thermal Vacuum chamber with horizontal or vertical mount baseplates.

- 80℃ to -80℃ temperature range.

- 12 T-type Thermocouple for user instrumentation.

- Ultimate pressure 1×10-6 torr.

- Mountable 12 ft vertical snout.

Snout Chamber

- 7 ft^3 chamber used for TVAC, bakeouts and materials testing. 13’x24′ baseplate.

- 1×10-7 torr ultimate vacuum at -60℃ to 70℃ temperature range.

- Snout compatible for boom deploy testing.

- 4 T-type Thermocouples for instrumentation use.

- TQCM.

- Electrical feed-thrus present.

Snout 2 Chamber

- 10cuft chamber with 20”w x32”d mountable baseplate space with 1/4×28 screws in 2”x2” grid ( Approximately 8.5ft^3 ).

- 90℃ to -80℃ temperature range at ultimate pressure of 1×10-7.

- 28 Type T thermocouples for customer use integrated into the system’s Thermal controller.

- Camera/lighting system to 60C.

- TQCM, RGA.

- Snout compatible for boom deploy testing. Electrical feed-thrus present.

- Attached to Silver 320 ISO 4Class 10k clean room.

X-Ray Chamber

- The X-ray generator sitting on a table against the East wall of the room and surrounded by a lead shield, hereafter called lead casing.

- The experiment table at the other end of the beamline, carrying the sample holder and the detector. This table is inside a vacuum chamber connected to a pipe extending all the way from the generator encasing to the vacuum chamber.

- The pipe enclosing the beam while it travels from one table to the other. This pipe is physically connected to the vacuum chamber, and therefore it can be in a vacuum.